Market and customer-specific

compounding

Our compounding offers set standards, our individuality makes an impact

We draw on in-depth expertise in the manufacture of innovative compounds made from conventional and bio-based raw materials. We tailor these compounds to the specific needs of our customers. Our unique know-how in polymers, additives, and fillers gives us the decisive edge, especially when it comes to developing solutions for sophisticated technical applications. Excellent mechanical properties and optimal processability make our compounds the perfect choice for a wide range of industries.

With seamless traceability of all raw materials along the entire supply chain, we ensure our compounds are available in consistently high quality and in the necessary quantities. Our customers can also rely on professional service at all times.

As a family-owned company, we are committed to sustainability. Driven by this philosophy, we develop concepts that conserve resources by using recyclates. We collect materials including recyclates from our own film production as well as re-granulated materials from our customers and as far as possible use them as feedstock for new compounds.

This also helps our customers reduce the carbon footprint of their products. To give customers the facts they need to select the most sustainable solution, we also carry out life cycle assessments for our StarBlend compounds which take into account the entire life cycle of these materials.

The figure below shows how the targeted integration of recyclates and bio-based raw materials significantly reduces the carbon footprint.

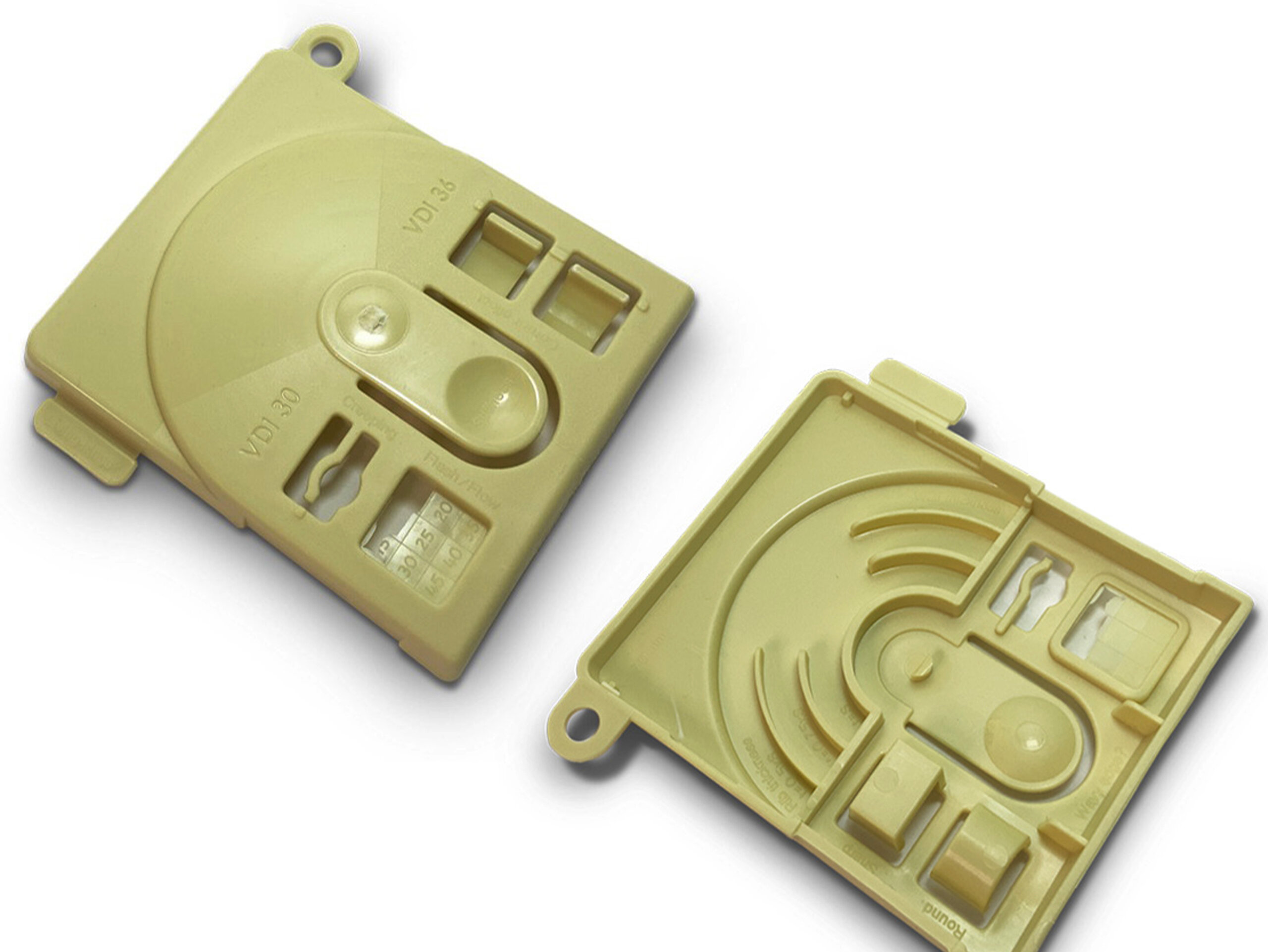

With our compounds, SÜDPACK is a member of the POSITIVE PLASTICS initiative. This organization compiles sample kits of polymers suitable for injection molding that have a reduced environmental impact and help create a functional circular economy. With this special form of sample sets, POSITIVE PLASTICS aims to demonstrate all the significant mechanical and optical properties of each material. That helps designers and product managers to gain a better picture of how the material could look in the finished product.

In Kit 3, SÜDPACK presents its StarBlend PP 004-01 R T20 N compound containing 70% PP recyclate.

Our compounds stand out for excellent mechanical properties and optimal processability. This makes them ideal solutions for various industries.

Whether you manufacture toothbrushes, plastic fittings for vehicles, household appliances, cable sheathings, cosmetics packagings, seals, window profiles, or packaging solutions – StarBlend® compounds are ideal for a whole range of applications in consistently high quality.

Our compounds are ideal for injection molding applications in the manufacture of consumer goods or consumer goods packagings, including products such as hygiene articles, toothbrushes, disposable razors, and packagings for cosmetics and cleaning agents.

They feature high flexibility, surface quality, and scratch resistance.

Our compounds can be used for manufacturing plastic packagings, e.g. bubble wrap or laminated films as well as rigid containers such as canisters and tanks.

Your key advantages: optimal protection against UV and weathering as well as media permeability tailored to your requirements.

SÜDPACK compounds are ideal for use in housings for household appliances, handles, boxes, and garden tools.

They feature high flexibility, surface quality, and scratch resistance.

Excellent mechanical properties and optimal processability make our compounds the perfect choice for automotive engineering.

They can be used e.g. for interior components, engine covers, floors, and driver protection.

SÜDPACK compounds are genuine all-rounders – and can be used in extrusion, injection molding, and thermoforming processes. They are ideally suited for furniture, tables, cover panels, rear panels, and protective films.

With optimal value for money, our compounds are particularly suitable for products that are used in the civil engineering and construction industry. For example in the form of strips, pipes, light wells, protective sheeting, underlays, and membranes.